Air Regulators

Auxiliary Equipment for FREE - Air Tubing Extrusion

“Air controllers are an integral part of a medical extrusion line. They are used in free extrusion of medical tubing for two reasons: sizing and structure.” Mike Ferrandino, Medical Extrusion Consultant (www.medicalextrusion101.com)

Air Support (assist) or Pressure used in profile extrusion equipment is necessary to maintain the required tubing dimensions when free extruding a tube. By controlling the extrusion rate along with the internal air pressure of the tubing, you can achieve the correct values for the outside diameter and wall thickness and maintain ovality. By locating your air pressure regulator close to the DIE and injecting it through the center of the pin that makes up the inner part of the extrusion die, and directly into the semi-fluid tubing. Diameter variations can be caused by the even the slightest pressure change during the extrusion of thin-walled products.

Our regulators can control the pressure even when a cut is made or during spooling of the tubing. Medical tubing has gotten so small that it is very hard to see that it is a tube and not just a thread. We have customers making tubing with 29 lumens.

“Air control is so often overlooked, almost like an afterthought. The “pay me now or pay me later” adage is true in this case. I’ve seen instances where someone will spend over half a million dollars on an extrusion line, but balk at a $5K/10K/$20K investment for the air controls. The one-time capital investment will be written off over a set period of time, not paying the money up front will eventually show up under COGs until the time is spent analyzing the self-induced problem and then the money will be spent, again”

– Larry Alpert, Past President of Biomerics Advanced Extrusion/ now at Graham American Kuhne

What sets us apart?

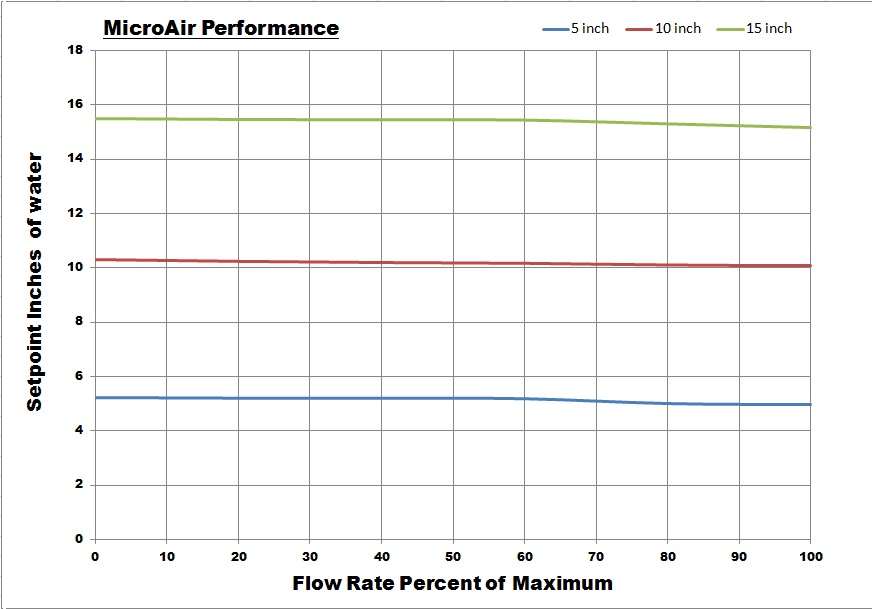

Our MicroAir Regulators and Controllers are the industry standard. The accuracy, stability and repeatability at the lowest pressures down to below 1” of water make our units the best for small diameter medical tubing. MicroAirs can respond instantly to changes in air flow to maintain the correct pressure for tube sizing. All units are built to order and have a 3-year warranty. Units are built in a stainless steel box with the highest quality parts so no spare parts are required. Low maintenance and rarely returned for repair.

Many MicroAirs are still in use for 15 – 20 years under constant usage. Calibration is not required as the unit is factory set before shipping. No installation needed.

MicroAir units are sold worldwide from our Shrewsbury, Massachusetts facility and can be purchased with your new extrusion line through Graham/AK Brand, Davis-Standard, Conair, RDN and Gimac. Micro-air units are accepted by your Guill Tool extrusion crosshead DIEs.