Services

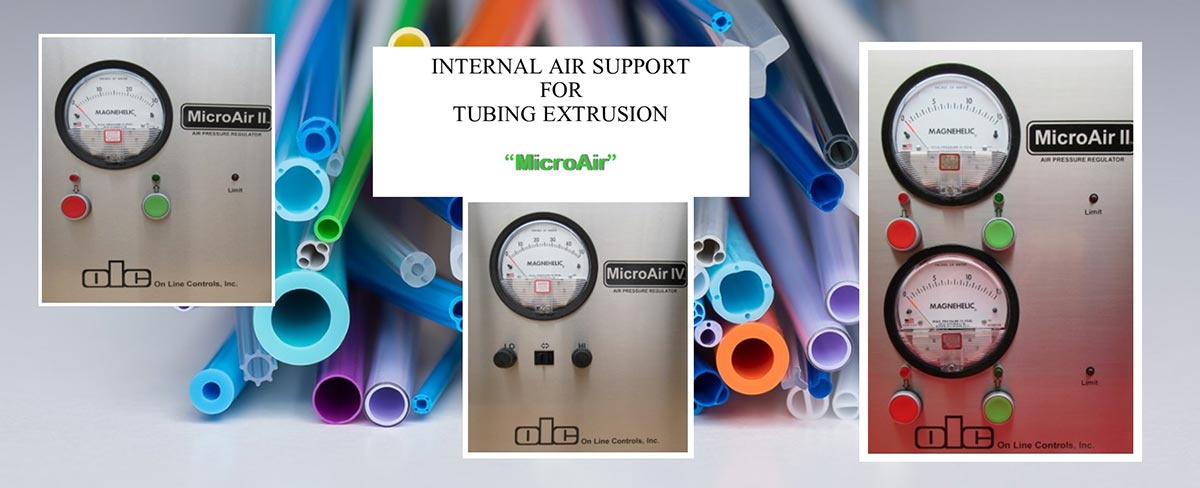

Technical support for MicroAir

ultra low air pressure regulators and controllers

Fast customer service is very important to us. Having an extrusion line down can be very costly. Our MicroAir units have a life span of 10 – 20 years. Any air pressure unit less than 10 years old can be serviced usually in one day. Older units can be sent in for evaluation. Note: that MicroAir’s with a serial number lower than 7000 are not repairable as the internal body has been worn out by 20 years of use. New units have much better precision and stability. All MicroAir units are covered by a 3-year manufacturers warranty. Each MicroAir is made to order, assemblied in house and pressure tested to give the highest precision pressure control during your extrusion process. MicroAir units do not need to be re-calibrated nor does the damping fluid ever have to be refilled if unit is kept vertically upright.

If you are having problems with your MicroAir regulator, we suggest the following steps before returning for repair:

Check that unit is:

- Mounted securely in a vertical position.

- Input and output connections are not damaged.

- Oil cup is approximately 7/8 full. Flapper valve needs to be immersed in oil.

- Check that the input air is approximately 50 psi. You may need an air regulator before your MicroAir to lower the input air down to 50 psi – a cheaper $20 unit is fine. MultiAir units require more air 55 – 65 psi.

- Verify you hear air expelling from the valve into the case.

- Note, if off line testing, temporarily plug output to simulate working line.

- Check that Flow Valve is open (Counter Clockwise) – check sticker in unit for its requirement.

- (1 turn for 2-10”, 2-3 turns for 15-30”, 3-4 turns for 3 psi and 4-6 turns for 5 psi).

- Air volume adjustment is described further in your users manual.

- Disconnect auto controlling electrical connections to the terminal strip (motorized units only) and retest unit to verify controlling input is not causing erratic operation.

- For none operating unit, always check fuse in power input before sending in unit for repair.

- If you are having problems with our Dual or MultiAir 3-channel or 4 channel units, please call customer service for additional help.

- If none of these steps correct your problem, please return the unit for repair – See return instructions below.

Offline Testing

To off line test a MicroAir unit, you must plug the output. After connecting air to the input, turn the side knob until the meter indicates 0. Turn the manual adjustment knob in the opposite direction until the meter indicates full scale.

Return for repair

Note: If returning a MicroAir for repair, please EMPTY and wipe out OIL DAMPING CUP. A clean up charge will be added to the repair, if unit is shipped with oil. Replacement damping fluid will be supplied with repaired unit. Also take off any pad lock before returning to OLC.

- Pack in box with sufficient packing material so no damage will result in shipping.

2. Include a brief description of the problem and a name and phone number of person to contact if we have any questions or need a purchase order, and a return address.

3. Ship to our facility:

On Line Controls, Inc.

Repair Department

697 Hartford Turnpike, Suite E

Shrewsbury MA 01545 USA

You will receive a call from our customer service department after the unit is received and tested with the cost of repair. A Purchase Order for the repairs may be required if unit is out of Warranty. Most MicroAir repairs can be done in one day.

SERVICE for Motorized Potentiometers

Motorized Potentiometers built by On Line Controls, Inc. can be returned for repair or rebuilding. Delivery will depend upon available parts. Our service department will also try and repair older (OEM) ETI motorized potentiometers (MC, MAC, ME series) built in the 80’s and 90’s. The clutch on your new motorpot has been factory set. Any adjustments may make the unit inoperable and void the warranty.